Why build a leaf in the lab? For one, it could lead to the design of novel photosynthetic materials or materials with improved and tunable functions. It could mean better batteries and artificial tissue. To do so, though, requires an exact understanding of the structure of plant leaves. That’s the goal behind a newly launched project co-headed by Corey O’Hern, professor of mechanical engineering, physics, and applied physics.

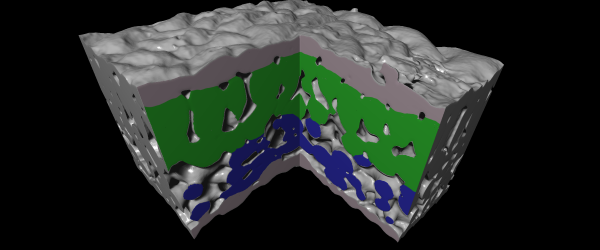

A focus of the project is building an in silico leaf, that is, a complete computer model that recapitulates the development of a leaf. To build a faithful model, the researchers will need large experimental datasets on the microstructure of plant leaves. For that, they will rely on x-ray studies of actual leaves taken by large synchrotron machines. It’s funded with a $750,000 grant from the National Science Foundation’s division of Civil, Mechanical and Manufacturing Innovation (CMMI) and its program in biomechanics and mechanobiology.

“It’s just like an x-ray of your body, except that it provides a three-dimensional reconstruction of the leaf tissue,” said Corey O’Hern, one of the co-principal investigators of the project, and professor of mechanical engineering, physics, and applied physics. He’s collaborating with Adam Roddy, a professor of environmental studies at New York University.

“It’s just like an x-ray of your body, except that it provides a three-dimensional reconstruction of the leaf tissue,” said Corey O’Hern, one of the co-principal investigators of the project, and professor of mechanical engineering, physics, and applied physics. He’s collaborating with Adam Roddy, a professor of environmental studies at New York University.

“Adam is in charge of using 3D imaging to characterize the diversity and function of leaf tissues,” O’Hern said. “I will take the lead in the computational modeling. In general, there are two main tasks when attempting to develop new biomaterials. One is to fully understand the biological material and all its components, and the second is to try making it in the lab using the components. This project focuses on the first task for plant leaves.”

These combined experimental and computational studies represent one of the first investigations into how simple biophysical rules can explain the development and diversity of complex, three-dimensional plant tissues. The results will reveal fundamental design principles for the porous tissue in the middle of leaves, known as the spongy mesophyll. This in turn will enable the design of novel materials that self-assemble and have specific tunable properties and mechanical responses. These could include new catalytic materials for batteries. In the medical field, it could mean new ways to make artificial tissue or tissue scaffolds.

“Right now, we can’t make artificial leaves,” O’Hern said. “In particular, we can’t make a material with the photosynthetic efficiency of a leaf. But if we had a computational model of a leaf at every point along its developmental trajectory, then we would be closer to being able to make one.”

The researchers say the work will not only improve our understanding of cells and tissues in plant leaves, but it will also reveal how the structural properties of the spongy mesophyll tissue vary across species. That’s important because different species of plants use the same building blocks to generate radically different structures.

“If you can develop a computer model that recapitulates the developmental process and gets the correct final structure of the biological material, you’re halfway there,” O’Hern said. “You understand the biophysical process that occurs. Now you just have to actually make it in the lab. And since you know exactly how the development happens, you are closer to being able to recreate it.”

This story is adapted from the Yale Engineering news story of September 27, 2024. See below for the link to the original story.